Tittle of activity :

PCB fabrication...hardware step development

PCB fabrication...hardware step development

Objective :

Content/procedure :

PCB

Drawing: PCB drawing is designed using Protel DXP 2005. Once the PCB layout has

been correctly design, it is now prints out the layout on the A4 size

transparent OHP paper. Note that, two types of printers are allowed to print

the PCB layout, one is laser printer and the other is carbon type of printer

such as Photostat machine. Inkjet and dot matrix type of printer will not work.

Content/procedure :

1.

PCB

Cutting: Cut photo PCB size according to the film size.

2.

PCB

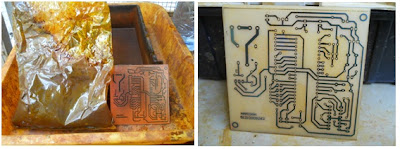

Photo Etching: Expose the photo PCB in photo etching kit for 8-10minutes.

3.

PCB

Developing: Wash the PCB using PCB developer (white powder) for 2 min.

4.

Acid

Etching: Etching is a process that removes materials from such us unwanted

copper from the PCB surface to achieve circuit design requirements. The etching

process used in this project is called chemical etch or pattern etch.

No comments:

Post a Comment